Instrumented Bolt

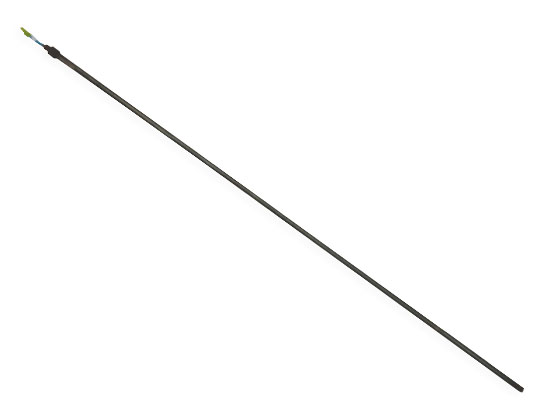

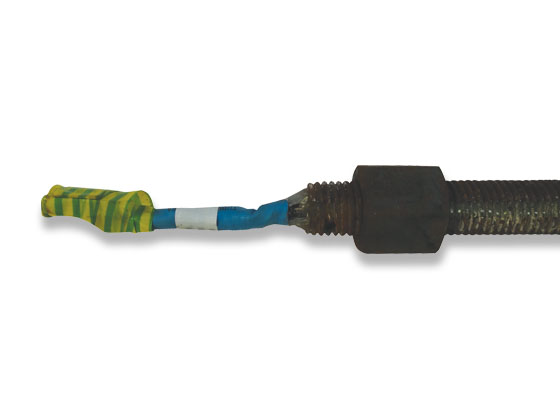

Instrumented bolt with 9 pairs of diametrically opposed gauges, includes 12 metre long readout cable (standard bolts up to 2.4m long).

Enquire

Please enter your details and we will be in contact regarding this product

Instrumented Bolt - Strain Gauged Rock Bolt

- Reliable accurate measurement of rock bolt load

- Measure full load profile at 9 locations

- Determine tension and shearing on bolt

- Determine encapsulation length

- Identify bonding and other bolt quality problems

- All bolt types available

- Lengths up to 5m

Manufactured in-house by SCT. The instrumented roof bolt allows the reinforcement performance of the bolts to be measured during the various mining stages.

The placement of rock bolts into the strata surrounding an underground opening allows them to respond to the strata movement and generate load. The generation of bolt load provides a clamping force that acts to confine the rockmass.

The instrumented (or strain gauged) rock bolt is used to measure the field performance of the rock bolt system by direct measurement of load at intervals along the bolt. Instrumented bolts are typically installed in underground excavations as part of the normal mining or tunnelling support cycle.

For fully encapsulated rock bolts, the determination of the load distribution of the bolt is a key design criteria. This enables the actual performance of the support system to be determined.

The instrumented rock bolt uses changes in gauge resistance to monitor bolt performance. It consists of nine pairs of foil wire resistance strain gauges that are bonded directly to the bolt at regular intervals. Each pair of gauges are arranged with the gauges diametrically opposed to determine the axial loading and bending moments (shearing) acting on the bolt.

The SCT instrumented bolt has the following characteristics:

- provides high accuracy quantification of load profile along the bolt

- resolves bending forces along the bolt

- can be simply installed

- can be installed using the same equipment and consumables as standard rock bolt installations

- has post yield capability

The instrumented bolt analysis incorporates the elongation characteristics of the rock bolt steel in both the pre and post yield states. The software has the capability to distinguish between the axial loading and bending derived strains when calculating bolt loads for both pre and post yield states. This provides realistic results in the post yield stage rather than simply assessing the elastic properties.

Depending upon the style of deformation occurring about the opening, the load generated in the bolts may act to confine discrete bedding or joint surfaces that are dilating/shearing or may be acting to confine areas of strata failure of intact rock. A fully encapsulated roof bolt is attached at each point along its length to the surrounding strata. As sections of the strata dilate due to rock failure, the bolt will attempt to resist this dilation by generating reactive forces across the dilation, as shown in the Figure below.

The load peaks will be located where the rock failure is occurring, with the load distributed along the length of the bolt. The nature of this non‑uniform load distribution will depend upon the load transfer characteristics of the bolting system.

Recent logging developments allow the instrumented bolts to be downloaded by the push of a button on a handheld logger. This advancement is more time efficient, increases the frequency of readings and reduces downtime.